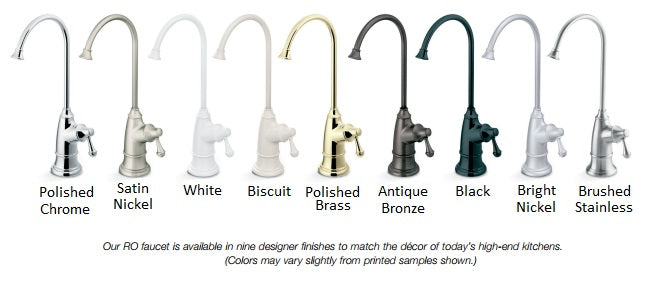

The Tomlinson RO Faucet comes in 9 finishes for a better match for today's designer kitchen. These lead-free faucet fits to most brands and makes a great upgrade from the basic faucet that come with most RO systems.

Features:

- 9 different finishes available: Polished Chrome, Satin Nickel, White, Biscuit, Polished Brass, Antique Bronze, Black, Bright Nickel, Venetian Bronze, Brushed Stainless Steel

- Air Gap: An air gap faucet which contains an empty space built in the base of the faucet. Air-gap faucets have three lines attached to them. (1) line from the tank to the faucet (2) a water line from the brine water side of your RO. (3) a drain line for the brine water that attaches to the drain saddle. Please check your local code to determine if an air-gap is required.

- Non-Air Gap: Non air gap faucets have no Air-Gap function built into them. These faucets have a single line from the tank to the faucet.

- Lever style handle

- Smooth operating ceramic disk element

- 360 degree swivel neck

- Protective spout tip that prevents after drip

- Modular air gap

- Preinstalled 1/4" tubing for quick connect

- Mounting hardware

- 2 year warranty

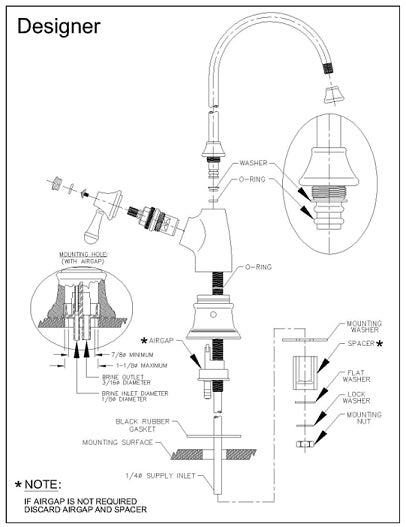

- Drilled hole size needed for Air Gap: 7/8"

- Drilled hole size needed for Non-AG: 1/2"

- Base diameter is 2 1/4" (57mm)

- Spout reach is approximately 5? (127 mm).

- Faucet height is 12? (305 mm).

- Pressure rating is 125 PSI/8.6 BAR.

- Flow rate is 1.0 gpm/3.785 lpm at 35 PSI/2.32 BAR.

- Temperature rating is 40°F/4°C to 150°F/66°C.

- NSF/ANSI 61-9 & 372

RECOMMENDATIONS:

- Read and understand all instructions before starting this installation!

- This faucet is for use with cold water supply only. WARNING €“ DO NOT USE FOR HOT WATER APPLICATIONS.

- Wear eye protection while using any tool to avoid injury.

- Determine where you will install the faucet. If using existing cut out in sink, it must be a minimum of 7/8" diameter and no larger than 1-1/8" diameter hole. If additional cut out is required, a 7/8" diameter hole is preferred.

- Stainless Steel Sinks: you'll need a 7/8" diameter knockout punch or drill with the appropriate size drill bit, available at most hardware stores.

- Porcelain or Cast Iron Sinks: special tools are required to drill through these materials. If you are not familiar with this process, you should consider having this done by a professional plumber.

- WARNING DO NOT ATTEMPT TO DRILL WITHOUT THESE SPECIAL TOOLS, AS YOU MAY DAMAGE YOUR SINK!

INSTRUCTIONS:

Step 1: Assembling Faucet With Air Gap For RO System

If faucet is being installed without an RO unit, skip step 1 and go to step 2.

Locate the air gap (refer to figures on opposite side). The air gap has 2 different size barbs, a small barb which is the brine inlet and a large barb which is the brine outlet. Attach a 1/4" outside diameter (.040 wall) tube (not supplied) to the brine inlet. Attach a 3/8" outside diameter (.060 wall) tube (not supplied) to the brine outlet (see note below). Once these tubes are in place, slide air gap assembly over threaded copper tube and align key on air gap with keyway in the base of faucet.

NOTE: It is important that enough tubing be installed on the brine inlet and brine outlet of the air gap so that installation of RO unit can be completed. Excess tubing can be trimmed to the proper length after faucet is mounted. Tubing is not supplied with faucet. Installation must be in accordance with local plumbing codes.

Step 2: Install Faucet

Non RO applications may discard air gap and spacer. Locate mounting hardware (refer to figures on opposite side). This will consist of six items; a black rubber gasket, a steel mounting washer, a white spacer (use if needed), a small steel Fl at washer, a steel lock washer, and a brass mounting nut. With black rubber gasket in hand, feed tubing from faucet through rubber gasket. Align rubber gasket with bottom of base. Next, add remaining 5 parts to the threaded copper tube loosely (do not tighten). Parts are to be assembled in the same order listed above, except for steel mounting washer, set this aside (do not discard). Next feed all tubes and mounting hardware into the mounting hole in sink using care, as there may be sharp edges if a new hole has been made. With faucet base and gasket seated over mounting hole, take the steel mounting washer and slide it between mounting surface and white spacer (if spacer is not being used, slide between small steel washer and mounting surface) keeping in line with threaded copper tube. Tighten brass mounting nut so that faucet barely moves against mounting surface, adjust faucet to desired orientation on sink. Tighten mounting nut, do not over tighten. With faucet in place and tight, plumbing connections can be completed.

Step 3: Plumbing Connection

If using an RO system, see directions provided with RO unit for final connections.

To connect cold water supply line when not using an air gap (without RO system), locate ¼" diameter blue cold water inlet tubing (supply inlet) that passes through threaded copper tube. Connect this tube to any cold water supply line with the use of a saddle valve (not provided) or any other approved method (consult local plumbing code).

NOTE: Removal of the 1/4" diameter blue cold water inlet tube (supply inlet) from threaded copper tube will void warranty.